top of page

Challenger 4

Increase Your Harvest

Challenger 4

4 Rows Forage Harvester

540 RPM

PTO WORKING CYCLE

280CM

WORK WIDTH

140 HP

MINIMUM POWER REQUIREMENT

Take a Close Look

Explore the Challenger 4 from every angle with 360-degree animation.

Low Power Requirement

Advanced Safety System

Gear Transmission and Cut Size Adjustment

In front of you is the first and only four-row silage machine in the sector that can operate with 140 hp. Çelikel® proves once again with its engineering talent that large machines can also operate efficiently with low power requirements.

With the advanced safety system, in case of jamming and blocking in the mowing mechanism of the machine during harvesting, the clutch system in the gearboxes is activated while the harvested product is still at the entrance of the machine, preventing overloads that may occur in other transmission organs of the machine.

The unique transmission of the Challenger® 4 can adjust the front drum speeds according to the corn productivity by working with 4 forward and 4 reverse speed options. You can adjust the chopping length of the machine as you wish. With the Challenger® 4, effective silage making is completely under your control.

Front Drum

The Challenger 4® Series uses a balanced chassis and shaper drums. Equipped with balanced and sharp blades, the independent shaper drums will enable you to harvest crops without any difficulty, even under the most difficult conditions.

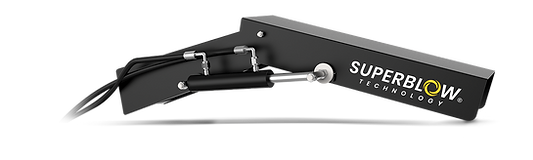

SuperBlow

Çelikel® created a system that has been added with fully balanced operation of the sweeping paddles and the inlet of the hydraulic funnel, thereby increasing the blowing force. Also we aimed to provide you with the efficiency that you desired by increasing the blowing capacity and the performance of sweeping paddles.

360° Rotating Funnel

In all the other equipments, rotation of the funnel is limited only to 90° but in Challenger® it has been increased to 360° thanks to the new clamp system.

Reverse Ejection

In case of a blockage during operation, the gearbox’s reverse ejection feature allows you to run the machine in reverse, enabling you to easily resolve the issue.

Patented Flywheel

The flywheel system consists of 12 excellent cutting knives and 12 sweeping paddles. This adds a powerful blowing and perfect chopping quality.

Technical Specifications

You can review the technical specifications of Challenger 4 in the table below.

Eigenschaften | CHALLENGER 4 |

|---|---|

WORKING WIDTH | 280 cm |

MINIMUM POWER REQUIREMENT | 100 kW (140 hp) |

WORKING POSITION | Front / Rear |

LENGTH (WORKING POSITION) | 2600 mm |

HEIGHT (WORKING POSITION) | 4165 mm |

HEIGHT (ROAD POSITION) | 2475 mm |

WIDTH (WORKING POSITION) | 4115 mm |

WIDTH (ROAD CONDITION) | 2920 mm |

WORKING CAPACITY | 5000 - 6000 m² / hour |

NUMBER OF THROWER BELTS | 12 |

NUMBER OF EDGING BLADES | 12 |

NUMBER OF SHREDDER BLADES | 12 |

NUMBER OF FIXED BLADES | 1 |

SHREDDING SIZE | Adjustable (3 - 10 mm) |

WHEEL SIZE | 10.0/80-12-UN5 |

NUMBER OF WHEELS | 2 |

THREE-POINT HITCH SYSTEM | Category II - III |

WEIGHT | 1770 kg |

INDEPENDENT HYDRAULIC | - |

HYDRAULIC CONTROL POSITION | Standard |

NUMBER OF CIRCULAR BLADES | 6 |

GRAIN CRUSHER AND SHREDDING SYSTEM | •Custom Designed Edger

•Knife-Top Surface

•Shredding Blades

•In-Hopper GGG60 Cast Crusher (Optional) |

SAFETY SYSTEM | Dual Power Transmission Belt |

MACHINE MOVEMENT TRANSMISSION | Gearbox and Flexible Transmission Combination |

HYDRAULIC MIDDLE ARM | Optional |

TEMPORARY REVERSE OPERATION | - |

PTO OPERATING SPEED | 540/750 RPM Rear, 1000 RPM Front |

Documents

You can download the documents we have prepared below so that you can find all the details you are wondering about.

1/1

Other Products

You can examine different subgroups of the same product group by clicking on the images below.

Calabria

Double Chop Forage Harvester

bottom of page

%20copy.png)